Views: 0 Author: JINCHEN/JINGCHENG Publish Time: 2026-01-30 Origin: JINCHEN/JINGCHENG

What is a clamp pipe

The first impression was, "Isn't a clamp pipe just a plastic tube?"

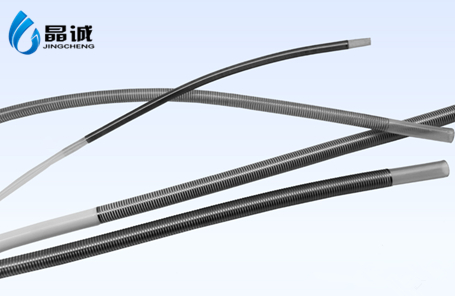

Yes, it's the pipe in the picture above. Essentially, it's just a plastic pipe, but this pipe is no ordinary one.

Regarding the forceps tube, let's first share several of its uses: 1) It is an independent tube inside the endoscope wall, used for the repeated insertion and withdrawal of surgical instruments such as biopsy forceps, injection needles, and electrocautery, assisting doctors in completing operations such as sampling, hemostasis, and resection within the body. 2) Some of the designs also serve as perfusion or suction purposes, for flushing, suctioning secretions or inflating to maintain a clear field of vision.

Why is it said that this pipe is not simple?

In the application of forceps tubes, many performance requirements have been put forward, such as:

1) Bending flexibility. It is necessary to repeatedly bend without collapse under a minimum bending radius of 5 to 10 mm to ensure that the instrument can still pass smoothly when the endoscope is bent

2) Radial compressive resistance: After applying a certain radial load to the clamp tube, a certain contour inner cavity size should be maintained to prevent instrument jamming. 3) Sealing/leakage: Maintain no leakage for a certain period of time under a certain water pressure or air pressure to prevent body fluids or flushing fluids from entering the endoscope. 4) Internal friction coefficient: The dynamic friction coefficient of the inner wall against stainless steel instruments should be ≤0.15. Reduce insertion force and wear. 5) Biological safety, high-temperature disinfection resistance, etc.

Here are two common design structures for clamp tubes

1) PTFE extruded tube + bending section spring winding: First, a single-layer PTFE tube is extruded, and then a spring is wrapped around the bending part to enhance the bending resistance. This type of design has a relatively low cost, but its drawbacks are also quite obvious. It has poor bending resistance (with a large bending radius), and its outer diameter is relatively large, making it difficult to install. This structure is currently mainly used in older endoscope models. There are many domestic suppliers of this type of clamp tube, and almost all of them have achieved domestic production.

2) PTFE inner layer +PTFE outer layer: First, a single-layer PTFE tube is extruded as the inner tube, and then an ePTFE foamed tube is wrapped around the outer layer through a special process. This design perfectly combines the advantages of PTFE and ePTFE, achieving both smoothness and the excellent flexibility of the foamed tube, meeting the requirements of the clamp tube being both soft and resistant to bending. This technology originated from Olympus first It is also the first choice for domestic manufacturers at present.

The hot melt hoses produced by JINCHEN Company can be used for 5 to 6 years under normal usage conditions.

Therefore, it is recommended that everyone purchase high-quality hot melt PTFE hoses.

At the same time, how to use and maintain them correctly to ensure a longer service life of the hot melt PTFE hoses.

Contact me:

eva@shenzhenjingcheng.com

WhatsApp:+8613302625821